Introduction

The global manufacturing landscape is undergoing a seismic transformation, driven by rapid advancements in technology and the increasing demand for efficient, sustainable, and data-driven production processes. The smart manufacturing market, projected to reach unprecedented heights by 2027, is at the heart of this revolution. Smart manufacturing, which leverages cutting-edge technologies like internet of things (IoT), artificial intelligence, and robotics, is reshaping industries worldwide, driving productivity, reducing costs, and enhancing product quality.

Key Drivers of Growth

The growth of the smart manufacturing market is fueled by several significant factors, each contributing to its widespread adoption and transformative impact on the global industrial landscape.

1. The Push Toward Sustainability and Energy Efficiency

Sustainability has emerged as a critical focus for industries worldwide, driven by mounting environmental concerns, stricter regulations, and consumer demand for eco-friendly practices. Smart manufacturing aligns seamlessly with these goals by offering innovative solutions to reduce waste, lower energy consumption, and improve resource utilization.

Advanced manufacturing technologies enable real-time energy monitoring and optimization, ensuring processes are as efficient as possible. For instance, smart factories utilize sensors to track energy use across production lines, identify inefficiencies, and implement corrective measures in real time. By adopting these methods, industries can significantly reduce their carbon footprint, contributing to global climate action initiatives.

In addition to environmental benefits, these advancements translate to substantial cost savings. Lower energy bills, reduced material wastage, and streamlined operations make sustainability not just a moral imperative but also an economic advantage for manufacturers.

2. The Role of the Industrial Internet of Things (IIoT)

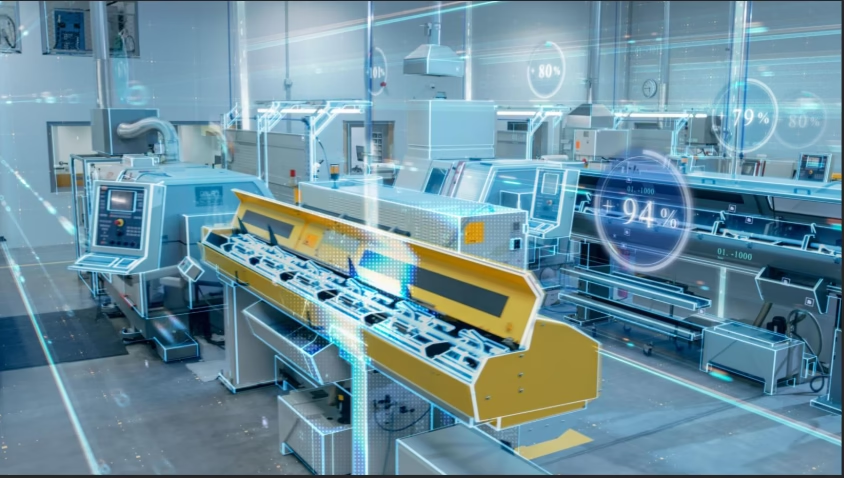

The Industrial Internet of Things (IIoT) has been a game-changer in modern manufacturing, revolutionizing the way factories operate. IIoT involves the integration of physical devices, sensors, and machines with digital systems, enabling seamless communication and data exchange. This interconnected ecosystem allows manufacturers to achieve unparalleled levels of efficiency and productivity.

One of the most transformative applications of IIoT is predictive maintenance. Traditional maintenance practices often involve scheduled check-ups or reactive repairs after a failure. Predictive maintenance, powered by IIoT, uses real-time data from connected devices to predict potential equipment failures before they occur. This reduces unplanned downtime, extends the lifespan of machinery, and saves millions in maintenance costs annually.

Additionally, IIoT facilitates real-time monitoring of production processes. Manufacturers can track every aspect of their operations, from raw material input to finished product output, ensuring consistent quality and identifying bottlenecks. This capability enhances decision-making, allowing businesses to respond swiftly to changes in demand or production challenges.

3. Growing Demand for Personalized Products

Consumer preferences have evolved significantly, with increasing demand for customized and personalized products. From bespoke fashion to tailored medical devices, customers today seek products that align with their unique needs and preferences.

Smart manufacturing systems are uniquely positioned to meet this demand. Traditional manufacturing models, which rely on mass production, often lack the flexibility to accommodate customization without incurring high costs. In contrast, smart factories leverage advanced technologies such as additive manufacturing (3D printing), robotics, and AI-driven design tools to produce personalized products efficiently.

For example, in the automotive industry, customers can now configure vehicles with custom features and finishes, which are then seamlessly integrated into the manufacturing process. Similarly, in the healthcare sector, 3D printing enables the production of patient-specific medical implants and prosthetics, enhancing patient outcomes.

This ability to balance customization with efficiency not only improves customer satisfaction but also opens new revenue streams for manufacturers. Companies that embrace personalization gain a competitive edge, fostering customer loyalty and expanding market share.

4. Enhanced Connectivity and Data Utilization

Another driver of growth in smart manufacturing is the increasing ability to collect, analyze, and utilize vast amounts of data. Advanced analytics and machine learning tools allow manufacturers to gain deeper insights into their operations. For instance, data from production lines can reveal trends, inefficiencies, and opportunities for improvement.

The connectivity provided by smart systems also facilitates better supply chain management. Manufacturers can collaborate with suppliers and distributors more effectively, ensuring timely delivery of materials and products. This interconnected ecosystem minimizes disruptions and enhances overall efficiency.

In summary, the growth of smart manufacturing is propelled by its alignment with sustainability goals, the transformative potential of IIoT, the rising demand for personalized products, and the power of data-driven decision-making. These drivers are shaping the future of industry, positioning smart manufacturing as a cornerstone of economic growth and innovation.

Regional Trends

North America and Europe continue to lead the smart manufacturing revolution, owing to their strong industrial foundations and commitment to technological innovation. These regions have been early adopters of Industry 4.0 technologies, leveraging them to enhance competitiveness and sustainability.

Meanwhile, the Asia-Pacific region is emerging as a powerhouse in smart manufacturing. Countries like China, Japan, and South Korea are investing heavily in advanced manufacturing technologies. With robust government support and thriving industrial bases, the region is poised to dominate the global market in the coming years.

Developing regions, including Africa, are gradually recognizing the potential of smart manufacturing. Strategic investments and policy frameworks can enable these regions to harness the benefits of this technological revolution.

Challenges to Overcome

Despite its transformative potential, the smart manufacturing market faces several challenges. High initial implementation cost remains a significant barrier, especially for small and medium-sized enterprises (SMEs). The integration of advanced technologies requires substantial investment in infrastructure and training.

Cybersecurity concerns also pose a major risk. As manufacturing systems become increasingly interconnected, they are more vulnerable to cyberattacks. Ensuring robust cybersecurity measures is essential to protect sensitive data and maintain operational integrity.

Furthermore, the workforce must adapt to these changes. The shift to smart manufacturing requires a new set of skills, emphasizing the need for comprehensive training programs and educational initiatives.

The Way Forward

For countries like Ghana, the rise of smart manufacturing presents an opportunity to leapfrog into the future of industrialization. By prioritizing investments in technology, education, and infrastructure, Ghana can position itself as a leader in Africa’s industrial transformation.

Public-private partnerships will play a crucial role in driving this agenda. Collaborations between government, academia, and industry stakeholders can foster innovation, create job opportunities, and enhance competitiveness.

Additionally, adopting global best practices and tailoring them to local contexts will ensure the sustainable growth of the sector. With the right policies and investments, smart manufacturing can become a cornerstone of Ghana’s economic development.

As industries continue to evolve, smart manufacturing is proving to be more than just a trend – it is the foundation of a new industrial era. Organizations and nations that embrace this transformation will not only thrive but also lead the charge toward a more sustainable and technologically advanced future.

Author:

Abubakari Saddiq Adams, Business IT & IT Legal Consultant with a focus on IT governance and cybersecurity | Member IIPGH.

For comments, contact: +233246173369 | abubakrsiddiq10@gmail.com